A lesson from KFC: Biggest product shortage turned into PR masterclass

A non-traditional way of managing product shortages

Hello! I’m Caner and welcome to my newsletter - the SupplyChainist. Every Friday, I write about subjects within the supply chain management that I learned and keep learning along my 10 years of supply chain experience.

Good morning!

What keeps me up at night (other than my 5 months old baby) is the risk of going out-of-stock on the most critical items. These are the products that may cause you to close your restaurant, have empty-shelves in a retail store, or shut down your production.

Supply Chain is a complex world

1) Numerousness. Consider for a second about your current organization. Has the range of product offerings increased or decreased? New products are introduced at a higher rate than discontinuation of non-performing products. Companies add new SKUs, new pack/sizes, or new flavors all the time to address new consumer requirements.

More products mean managing more processes, suppliers, or customers.

2) Too many interactions. Consider the interactions between entities from first order to final customer delivery (+ product returns). Each step requires on-time and accurate execution. It is a chain. Even when the plan is "perfect," things will likely go wrong at the least expected times.

That's why also supply chains are fun because they are unpredictable. Every day becomes different as you operate in this uncertain environment.

Here is a non-exhaustive list of things that can go wrong

Truck or vessel breakdowns

Truck gets stuck in traffic congestion

The driver has run out of hours and can’t drive more to make that last delivery

Goods get damaged (temperature issues or physical product damage) in transit

Goods get stuck at the port

Warehouse loses the product

Supplier ships the wrong items

Supplier ships incorrect amount

In-house inventory counts were incorrect

Sudden shutdown of production facilities without notice

Purchasing order was never shipped

Purchasing order quantities placed were inadequate

Purchasing order was placed too late

Supplier’s equipment breakdowns

This is only a short list.

The traditional way of managing product shortages

Don’t have a shortage! Manage supply, inventory, and transportation proactively to match the demand and serve customers.

If there is a product shortage risk, investigate all options to mitigate that risk.

If the product shortage is inevitable, manage expectations and inform sales, marketing, and customers on what's happening and the plan.

Because out-of-stocks (especially long-term ones) can be so damaging, most companies don't want to be in that position. Therefore, the traditional mitigation plan is to work with sales and marketing to remove promotions that will cause demand reduction.

The reduced demand will cause the supply to last longer and may prevent going out-of-stock or out-of-shelf.

Sometimes whatever and how much we try, out of stock, will be inevitable.

In this case, KFC's marketing team showed everyone of a non-traditional approach on turning out of the stock situation into an award-winning PR campaign.

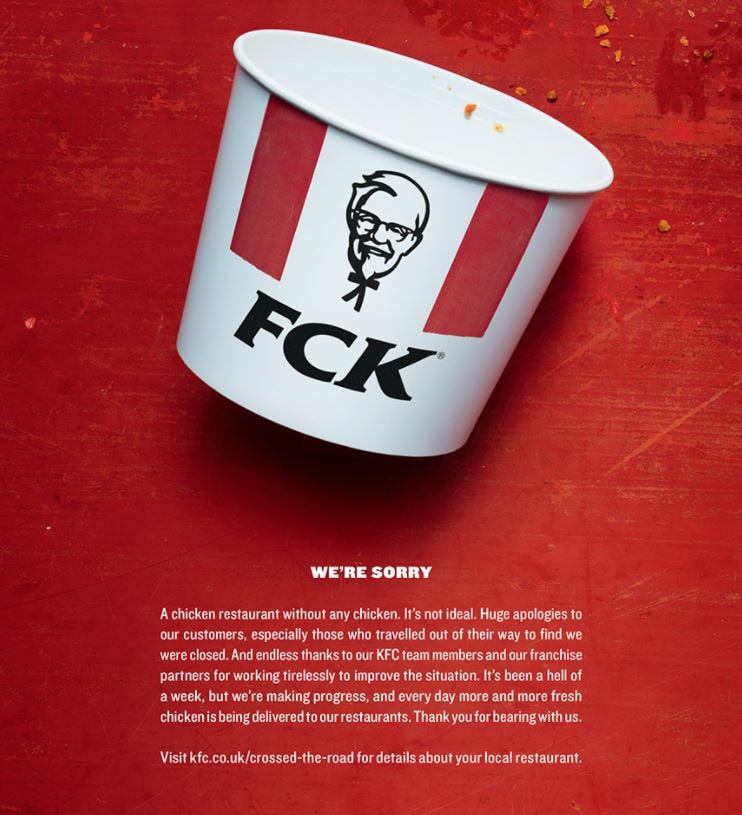

The KFC (or FCK) way of amazing marketing ad on managing an out-of-stock

In 2018, KFC shut down roughly all of its 900 restaurants in the UK and Ireland during one weekend as the company had a chicken shortage.

In response to managing the situation, KFC has printed the below awesome full-page apologetic ads in the newspapers.

How not forgive them?

In the first communications, the company mentioned a delay with a new delivery partner - DHL. This is a perfect example of supply chain uncertainty and complexity. Companies like DHL, UPS, or FedEx are the most established and reliable global logistics companies globally.

And of course, this is the internet, check how Burger King trolled KFC:

I can’t imagine the stress the KFC supply chain team had to go through with this shortage.

Despite all, this is a great example of taking something negative, seeing it as an opportunity, and making it positive. KFC’s newspaper ad got PR awards and is now seen as a marketing masterclass. It was also brilliant support from the marketing team to the supply chain team.

Thank you for being part of the supplychainist and have a great Friday :)

If you liked this issue and found it valuable, consider sharing it with friends:

If you haven’t subscribed to it yet, subscribe now:

By subscribing to the newsletter, you will get the weekly new edition to your inbox about the approaches that I discovered and keep learning to help you make smarter supply chain decisions.