When air freight becomes cheaper than sea freight?

Hello! I’m Caner and welcome to my newsletter - the SupplyChainist. Every Friday, I write about subjects within the supply chain management that I learned and keep learning along my 10 years of supply chain experience.

Good morning!

When companies purchase goods from overseas manufacturers, should they use ocean or air freight? How do you we actually know if one is cheaper than the other?

Typically air-freight rates are 5-10x more expensive compared to ocean freight rates.

However, it can be misleading only to use freight costs to calculate the total shipment costs.

Two weeks ago, I wrote about considering the Total Cost of Ownership when making supply chain and vendor decisions. The same concept applies when calculating total shipment costs. We must incorporate inventory holding costs when also making freight mode decisions.

Inventory holding costs recap

This is an annual cost that incurs for holding inventory. It’s estimated that a company will have a minimum of 25% inventory carrying costs on average. The % will vary based on the product. It includes the opportunity cost of capital, operating and storage costs (warehouse, equipment, labor, disposal), obsolescence, shrinkage, deterioration, depreciation, and insurance costs.

Why inventory holding costs impact total shipment costs

It's because different transportation modes have different lead times, which impacts:

The amount of inventory you need to place. The longer the lead time, the larger the inventory order. (Increases the storage and operating costs)

The amount of capital tied to an inventory that is in transit. The longer the lead time, the longer it takes to sell this inventory, the longer the inventory is converted into cash. (Increases the opportunity cost of capital)

Let me demonstrate how inventory holding costs affect the total shipping costs. We will assume moving 1 container of goods from Shanghai, China, to Vancouver, Canada. I will use 3 product categories to estimate if air or ocean-freight is a cheaper option.

Smartphones (e.g., Apple iPhone)

Running Shoes (e.g., Nike)

Washing machines (e.g., LG)

Average lead times between Shanghai and Vancouver

Ocean Freight:

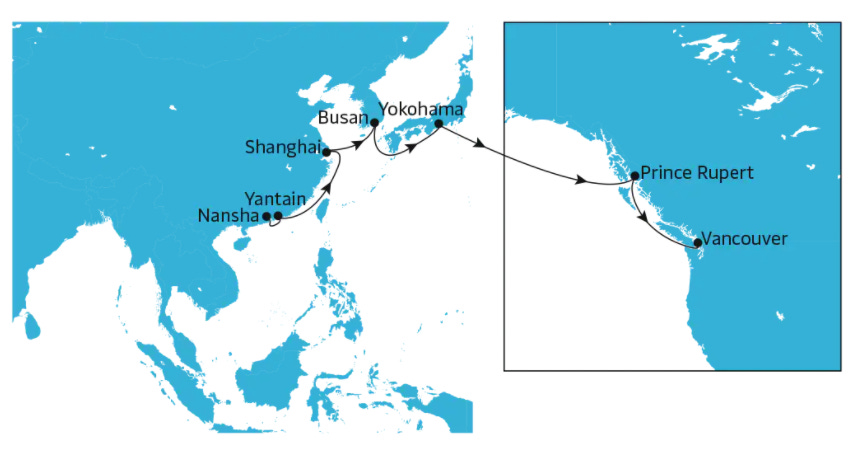

Based on the Maersk website, the Maersk route from Nansha, China, to Vancouver enables trade between Shanghai and Vancouver. This route roughly takes 21-22 days. The vessel will stop in 6 other ports, located in China, South Korea, and Japan, before arriving in Vancouver.

It’s important to note that all these stops can cause delays - that’s why ocean freight transit times are generally not as reliable as air freight transit times. Therefore, I will consider the total lead time will be 30 days considering all the potential delays occurring in ports due to backlogs.

Source: Maersk’s website

Air Freight:

Worldwide air-freight transit times are very reliable and vary between 1 and 4 days. Companies such as FedEx and UPS are some of the largest players in air-freight. We'll consider the air transit time as 2 days from Shanghai to Vancouver.

Cost comparison between air and ocean-freight

Calculations:

Freight costs are calculated based on weight.

Inventory holding costs (including capital cost) are calculated based on inventory value in dollars.

Total shipment cost = Freight + inventory holding cost

Based on these holding costs, lead times, and freight costs, shipping smartphones by air is $30k cheaper vs. ocean. The inventory holding costs you incur during ocean freight override the cost of airfreight.

Therefore, high-value items combined with high inventory carrying costs can override the high airfreight costs.

How smartphones incurred $69,903 inventory costs during ocean freight?

The holding cost is 20% - an annual cost.

Ocean lead time is 30 days. There are 365 days in 1 year.

The shipment value is $4,252,429.

Inventory holding cost formula = Shipment value * annual holding cost * lead time(days)/total days a year ($4,252,429 * 20% * 30/365 = ~$69k)

Other assumptions:

Inventory holding costs are 20% on average.

Air lead time is 2 days; ocean lead time is 30 days.

Airfreight is 10x expensive than ocean freight.

Estimated unit costs: smartphones ~$375, running shoes ~$28, washing machines ~$200. (Based on some Google research)

The spreadsheet is accessible here if you want to check the math behind it.

What if the inventory holding cost is 10%?

Ocean freight becomes the cheapest option for all 3 products.

Conclusion:

Transportation mode affects the lead times

Higher lead time increases inventory holding costs (including the opportunity cost of capital)

Holding costs will be tied to the inventory value, lead time, and the annual holding cost %

Higher holding costs caused during ocean-freight can override airfreight costs, making airfreight a more viable option

Are you now seeing some products in your supply chain you better air freight? When is the last time you looked at these total costs when making freight decisions? Please share with me below!

Thank you for being part of the supplychainist and have a great Friday :)

If you liked this issue and found it valuable, consider sharing it with friends:

If you haven’t subscribed to it yet, subscribe now:

By subscribing to the newsletter, you will get the weekly new edition to your inbox about the approaches that I discovered and keep learning to help you make smarter supply chain decisions.